Water-borne floor

Product Application

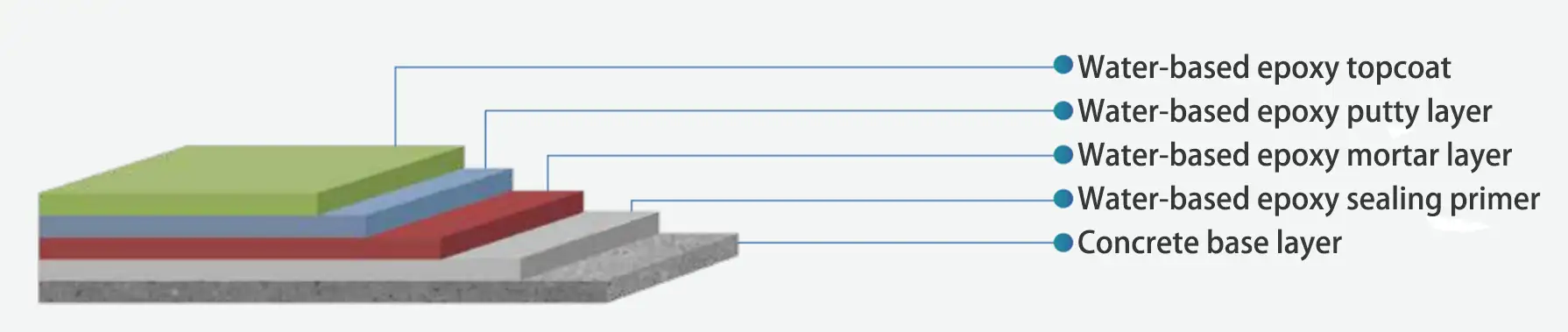

Water-borne Floor Coating Structure

Construction Technology

| Construction sequence | Construction process | Optional materials | Material quantity | Construction method |

| 1 | Concrete base layer | Grinding | ||

| 2 | Water-based epoxy sealer base coat | KS-301-1 water-based primer | Scraping | |

| 3 | Water-based epoxy mortar layer | KS-301-5 water-based mid-coat | Scraping | |

| 4 | Water-based epoxy putty layer | KS-301-5 water-based mid-coat | Scraping | |

| 5 | Water-based epoxy top coat | KS-302-4 water-based topcoat | Rolling |

| Process name | Specific practices and requirements |

| Base surface treatment | Before construction, the strength of the cement base surface must be above C25, the moisture content must be below 8%, and the height difference must be 3MM/2M; remove the cement slurry, old paint, oil stains, and adhered garbage and debris on the surface, and cut off the water supply. There must be no water accumulation on the surface; use a grinder to grind the cement base surface to ensure the flatness of the cement base surface. If there are cracks or hollow shells, deep V-shaped cutting, and cleaning should be done, and then epoxy mid-coat should be added with the appropriate amount of quartz sand and stirred evenly for repair and leveling; after grinding, use a vacuum cleaner to treat the base surface to thoroughly remove dust, oil stains, and other impurities on the base surface to improve the adhesion of epoxy floor paint to the base surface. |

| Application of base coating | Before construction, ensure that the cement base surface is flat, dry, free of water accumulation, dust, oil, and other impurities; mix the water-based epoxy transparent primer in a ratio of component A: component B: water = 1:3:2, stir with a mixer for more than 5 minutes, and ensure that the mixture is evenly mixed before construction; large-scale construction is mostly carried out by roller coating, and local missed coating can be repainted with a brush; if the ground is seriously sanded, the number of construction passes can be adjusted to ensure the sealing and reinforcement of the ground; mix ingredients according to the construction progress, and do not mix too much at one time. The prepared transparent primer must be used up within 30 minutes to avoid gelling and scrapping; after the construction is completed, the next process can be carried out after curing for 12 hours. |

| Intermediate coating of pressure-resistant layer | Before construction, ensure that the water-based epoxy transparent primer has been completely dried and cured, and the entire base surface is flat, dry, and free of dust and impurities; mix the color paint and curing agent in proportion, stir well, add the appropriate amount of quartz sand and quartz powder to make water-based epoxy mortar, and apply it evenly with a trowel to increase the thickness and compressive strength of the coating; a small amount of water can be added according to the construction viscosity, and it is recommended to be between 10% and 20%, but the amount of water added to each barrel must be consistent to avoid color difference; it is recommended to use roller coating, and it is not allowed to roll too thick at one time during construction. It is recommended to apply two times; according to the construction progress, the ingredients should not be too much at one time, and the prepared water-based epoxy middle coating should be used up within half an hour to avoid gelling and scrapping. According to the construction progress, the ingredients should not be too much at one time, and the prepared water-based epoxy middle coating should be used up within half an hour to avoid gelling and scrapping; after each middle coating is applied, it should be cured for 12 hours before the next middle coating can be applied. |

| Putty layer | After the construction of the middle coating, use sandpaper to polish the floor to ensure that the water-based epoxy middle coating has been completely dried and solidified, and the entire base surface is flat, dry, and free of dust and impurities; use water-based epoxy paint (middle coating) and quartz powder to make the putty according to actual needs. The requirements are to be flat and free of holes, knife marks, and sanding marks; after the first layer of putty is completely dry, use the same construction method to scrape the second layer of putty; the main function of the putty layer is to fill the gaps in the mortar layer, completely close the sand holes and pores, and make the floor more delicate. The material is limited to 30 minutes. |

| Grinding and cleaning | After the water-based epoxy middle coating putty layer is completely dry, use a polishing machine to perform a comprehensive polishing treatment on the whole, and polish the surface particles and other protrusions. Make it flat and smooth. After the middle coating is fully polished, use a broom or vacuum cleaner to clean it more than 2 times. |

| Roller coating of topcoat | Before construction, ensure that the epoxy putty layer has been completely dried and cured, and the entire base surface is flat, dry, and free of dust and impurities; mix the paint and curing agent in proportion, and stir with a mixer for more than 5 minutes to ensure that the mixture is evenly mixed before construction; a small amount of water can be added according to the construction viscosity, and it is recommended to be between 10% and 20%, but the amount of water added to each barrel must be consistent to avoid color difference; roller coating is recommended, and it is not recommended to roll too thick at one time during construction. It is recommended to apply two coats; the ingredients should be mixed according to the construction progress, and too many ingredients should not be mixed at one time. The prepared epoxy topcoat must be used up within 30 minutes to avoid gelling and scrapping. |

Color Customization

Finished Product Maintenance

·After the construction of the water-based floor is completed, it needs to be cured for 7-10 days before it can be put into use. During the curing period, water or other solutions should be avoided from soaking the surface.

·It is recommended that personnel entering the workshop change into rubber-soled shoes to avoid bringing mud and sand from outside into the workshop and scratching the floor.

·For hardware such as iron chairs, iron tables, iron shelves, etc., it is recommended to wrap their feet with soft plastic or rubber to avoid scratching the floor during use.

·The forklift needs to fully lift the pallet off the ground. Please pay special attention to the pallet corners when turning, and do not scratch the floor.

·Please use a soft mop or a wet and dry vacuum cleaner to clean the floor. It can be cleaned with clean water or detergent.

·Before the equipment enters the factory, it is recommended to lay a hard cardboard box as a bottom to avoid scratching the floor during transportation of the equipment.

·Please use hard or elastic rubber wheels for the wheels of carts and pallets. It is recommended to use them separately inside and outside the factory.