Water-based nano colorant

Details

| Specific advantages |

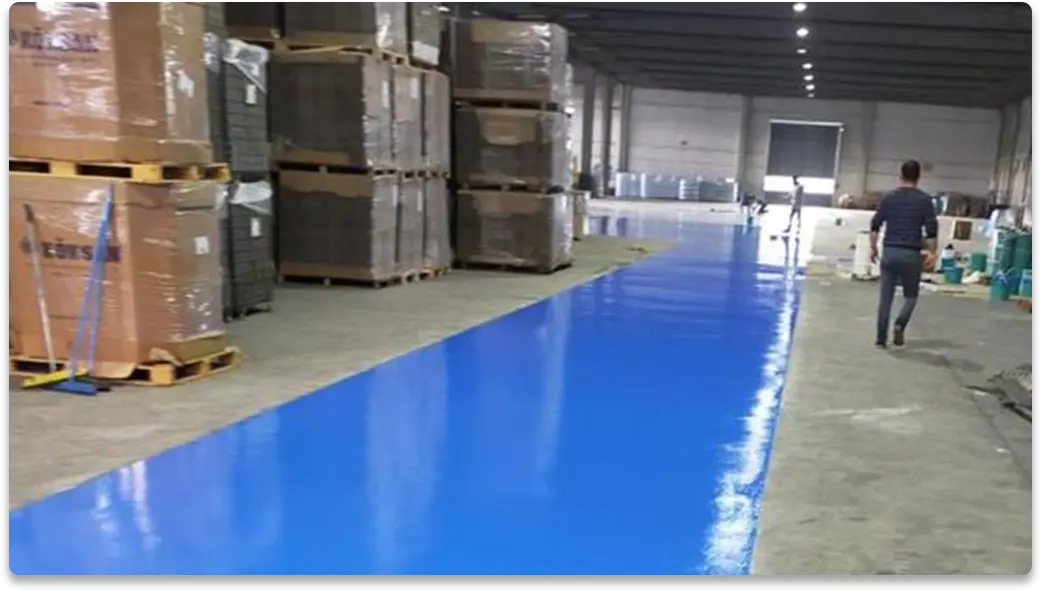

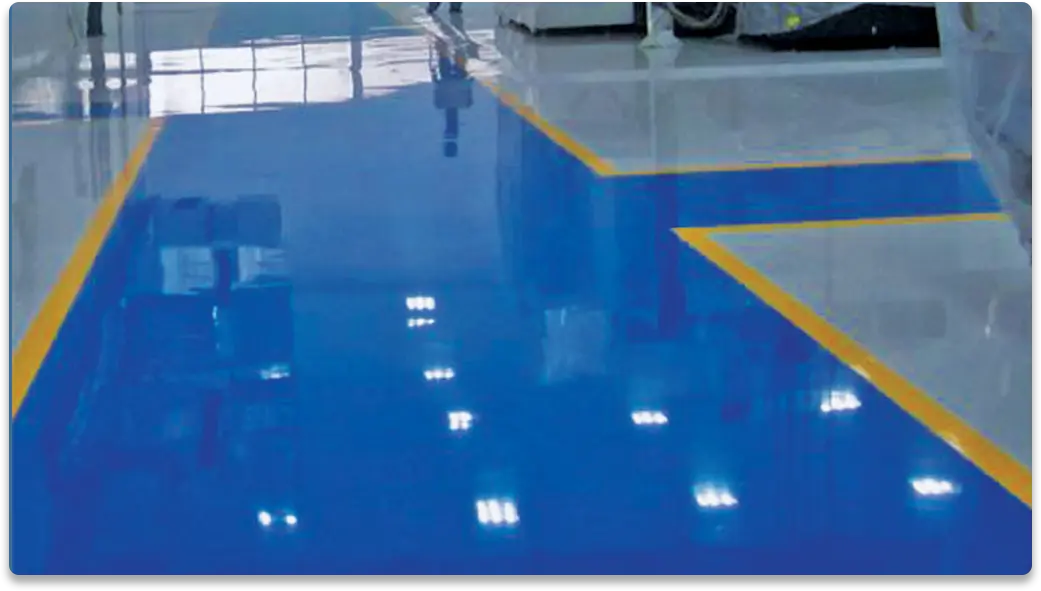

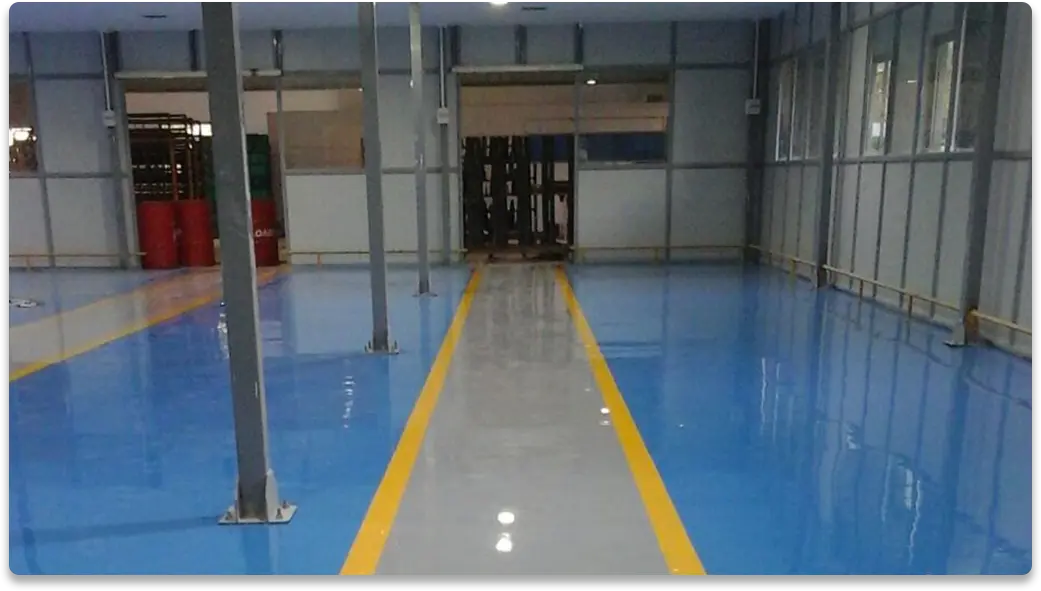

| 1. High dye penetration rate, pure color tone, can dye dark gray concrete floor into sky blue and light green. More suitable for large areas such as industrial plants and parking lots. |

| 2. Oily liquid has no odor, and the liquid poured on the ground cannot be ignited by a lighter. |

| 3. It has strong penetration and dyeing properties for the dense and bright concrete surface after curing and polishing. |

| 4. The dyeing process is simple and the dyeing is firm. First cure and grind, then dye, and form in one time. |

| 5. The dyeing is uniform and the material consumption is low. One kilogram can dye 10 square meters. |

| Features |

Specific features |

Hardness

|

After curing, the floor can improve the Mohs hardness. |

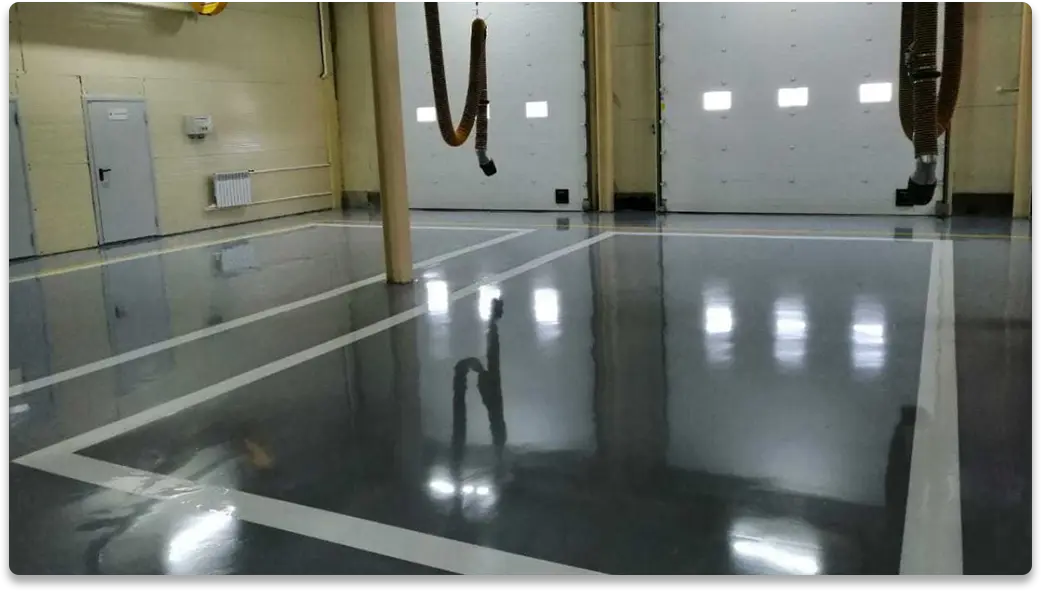

| Gloss |

After curing and dyeing, the floor shows a charming marble luster. |

| Sealed and impermeable |

The curing agent plays a sealing role and has an anti-penetration effect. |

| Dust and sandproof |

Forming a closed whole, and controlling the dust in the concrete from the gaps makes it easier to take care of. |

| Weathering resistance |

The treated floor has high hardness and a significant anti-weathering effect. |

| Abrasion resistance |

After using the curing agent, the floor is extremely durable, wear-resistant, and scratch-resistant. |

| Slip resistance |

After curing, the floor can reduce surface resistance and improve anti-slip properties. |

| Odorless |

After curing, the floor can reduce surface resistance and improve anti-slip properties. |

| Methods used |

| 1. Grind the concrete flat (grind to about 400#). |

| 2. The concrete must be dry, and its surface must be cleaned before construction. |

| 3. Protect the finished product in non-colored areas. |

| 4. Roll or spray the colorant evenly on the surface of the concrete to be colored, and apply the colorant repeatedly and evenly with a mop (dust mop) or roller until the colorant is evenly dried. |

| 5. Coffee, maroon, and yellow-green are generated by the superposition of two colors. When superimposed, wait for the previous color to dry before the next color. Antique effects can also be produced by uneven construction of two colors. |

| 6. If you want to further deepen the color, repeat the coloring (generally two or more times) after the previous colorant is applied and dried (more than 12 hours and the drying time is appropriately extended in a low-temperature environment) to achieve the best coloring effect. |

| 7. Dry naturally for more than 24 hours. After the colorant is safely dried, use a high-speed polisher (or floor scrubber) with an animal hair pad (or scouring pad) to polish the concrete surface clean. |

| 8. If you want to seal and cure the concrete after coloring, you can do it after the colorant has dried safely (more than 24 hours, and the drying time can be extended appropriately in a low-temperature environment). |

| 9. Use concrete protective agent for protective treatment or further grind to the finished product gloss required by the design. |