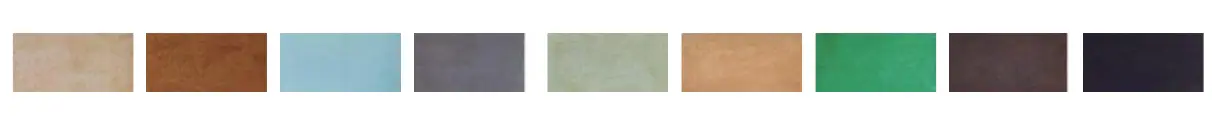

Water-based ionic colorant for concrete

Details

| Features |

Specific features |

| Hardness |

After curing, the floor can effectively improve the Mohs hardness. |

| Gloss |

After curing and dyeing, the floor shows a charming marble luster. |

| Sealed and impermeable |

The curing agent plays a sealing role and has an anti-penetration effect. |

| Dust and sandproof |

It forms a closed hole, prevents the dust in the concrete from separating out from the gaps, and is easier to take care of. |

| Weathering resistant |

The treated floor has high hardness and a significant anti-weathering effect. |

| Wear resistant |

After using the curing agent, the floor is extremely durable, wear-resistant, and scratch-resistant. |

| Anti-slip |

After curing, the floor can reduce surface resistance and improve anti-slip properties. |

| Environmentally friendly |

Use a safe and odorless formula to create a safe, clean and healthy environment. |

| Polishing concrete |

| 1. Dry-grind the concrete to 50# and harden it with concrete sealer (KS-503A). |

| 2. Dry-grind the concrete to 500#. |

| 3. The concrete must be dry and its surface must be cleaned. |

| 4. Protect the finished product in non-colored areas. |

| 5. One person uses a low-pressure sprayer to spray the colorant on the concrete surface (it can also produce an antique effect through uneven construction), and the other person follows closely with a dust pusher to repeatedly and evenly spread the colorant until it is completely absorbed by the concrete. |

| 6. If you want to further deepen the color, you can repeat the coloring after the previous colorant is applied and dried (more than 4 hours) to achieve the best coloring effect. |

| 7. Naturally dry for more than 24 hours (low-temperature environment appropriately prolongs the curing time). |

| 8. Use a high-speed polisher with a 2# diamond polishing pad to polish and remove the surface dust of the concrete. |

| 9. Use a concrete sealer to harden, fix the color, and polish. |

| Polishing concrete |

| 1. Use a wire brush to clean the floating slurry layer on the surface of the concrete-stamped concrete floor. |

| 2. The concrete must be dry and its surface must be cleaned. |

| 3. Protect the finished product in non-colored areas. |

| 4. One person uses a low-pressure sprayer to spray the colorant evenly on the concrete surface (it can also produce an antique effect through uneven construction), and the other person follows closely and repeatedly spreads the colorant evenly with a mop until the concrete is completely absorbed. |

| 5. If you want to further deepen the color, you can repeat the coloring after the previous colorant dries (more than 4 hours) to achieve the best coloring effect. |

| 6. Natural curing for more than 24 hours (low-temperature environment appropriately extends the curing time). |

| 7. Clean the dust on the surface of the concrete and apply a concrete protective agent. |