Polymer ramp

Product Application

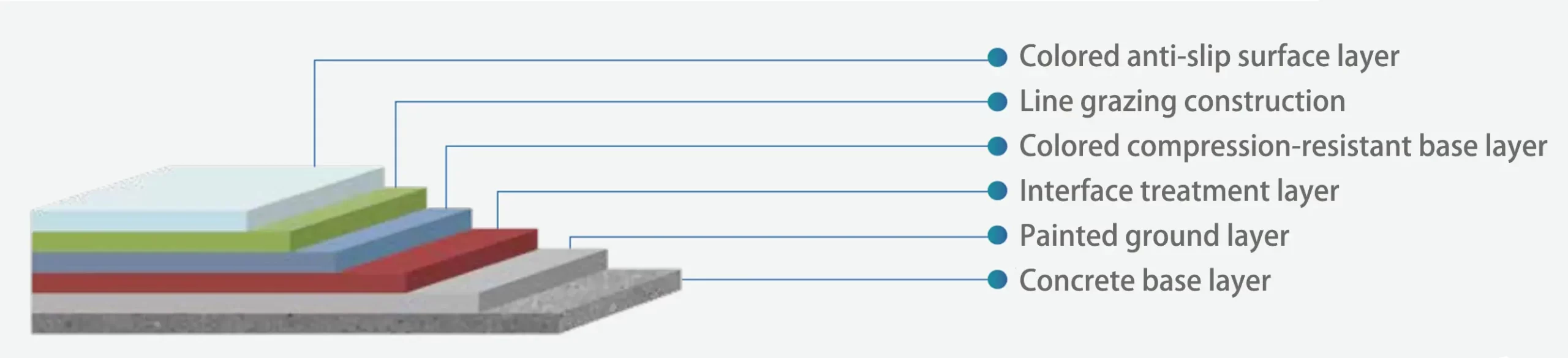

Polymer Ramp Coating Structure

Construction Technology

| Construction sequence | Construction process | Optional materials | Material quantity | Construction method |

| 1 | Concrete base layer | Grinding | ||

| 2 | Repair ground layer | Grinding | ||

| 3 | Interface treatment layer | KS-302-3 Water-based primer | Scraping | |

| 4 | Colored compression base layer | KS-302-2 Water-based resin | Scraping | |

| 5 | Line grazing construction | KS-302-1 Polymer powder | Scraping | |

| 6 | Colored anti-slip surface layer | KS-302-4 Water-based topcoat | Rolling |

| Process name | Specific practices and requirements |

| Base surface treatment | Use a 120-mesh or 60-mesh metal grinding head to evenly grind the floor to make it flat, and repair the damaged parts. |

| Application of base coating | Add water to the primer at a ratio of 1:2, stir it thoroughly, and roll the primer evenly with a roller, using 0.1 kg per square meter. |

| Intermediate coating for anti-pressure layer | After the primer is dry, add water to the water-based resin at a ratio of 1:1, and then mix it with polymer powder (color) at a ratio of 1:8-9, and mix it thoroughly with a mixer. |

| Sanding and painting | Pour the mixed material on the ground and scrape it evenly with a trowel. The amount per square meter is 4 kg, and the thickness is 2-2.5 mm. |

| Line laying construction | After the previous process has been dry for one day, paste the masking tape according to the design requirements of the traffic sign; add water to the water-based resin at a ratio of 1:1, and then mix it with polymer powder (color) anti-slip layer material at a ratio of 1:8-9, and stir it thoroughly with a mixer; pour the mixed material on the ground and scrape it evenly with a trowel. The amount per square meter is 4 kg, and the thickness is 3 mm. |

| Epoxy top coating | After drying for one day, apply the coating. Dilute the coating agent with water in a ratio of 1:2 and apply it evenly with a roller. The amount used per square meter is 0.1 kg. |

| Floor maintenance | After the surface coating is completed, the relevant construction materials and tools are removed from the site, and construction debris and garbage are cleaned up. The finished surface is tightly sealed and protected, and people are allowed to enter and walk after at least 24 hours. No mud or sand is allowed to be brought in. It usually takes 7 days for the paint film to be cured. During this period, other construction, transportation, installation, etc. should be avoided. |

Color Customization

Finished Product Maintenance

·After the epoxy floor is constructed, it needs to be cured for 7-10 days before it can be put into use. During the curing period, water or other solutions should be avoided from soaking the surface.

·It is recommended that personnel entering the workshop change into rubber-soled shoes to avoid bringing mud and sand from outside into the workshop and scratching the floor.

·For hardware such as iron chairs, iron tables, iron shelves, etc., it is recommended to wrap their feet with soft plastic or rubber to avoid scratching the floor during use.

·The forklift needs to fully lift the pallet off the ground. Please pay special attention to the pallet corners when turning, and do not scratch the floor.

·Please use a soft mop or a wet and dry vacuum cleaner to clean the floor. It can be cleaned with clean water or detergent.

·Before the equipment enters the factory, it is recommended to lay a hard cardboard box as a bottom to avoid scratching the floor during transportation of the equipment.

·Please use hard or elastic rubber wheels for the wheels of carts and pallets. It is recommended to use them separately inside and outside the factory.