Pervious concrete pavement

Product Application

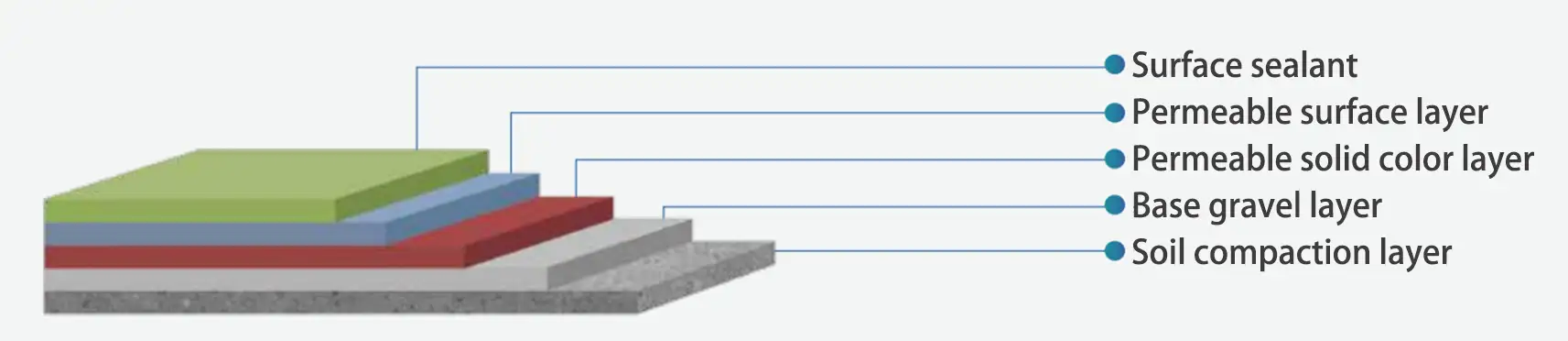

Pervious Concrete Pavement Coating Structure

Construction Technology

| Construction sequence | Construction process | Optional materials | Material quantity | Construction method |

| 1 | Plain soil compaction layer | Compacting | ||

| 2 | Base with a crushed stone layer | Compacting | ||

| 3 | Water-permeable plain layer | KS-406 concrete enhancer + cement + gravel + water | Compacting | |

| 4 | Water-permeable surface layer | KS-406 concrete enhancer + cement + color powder + gravel + water | Compacting | |

| 5 | Surface sealant | KS-406-1 concrete protective agent | Spraying |

| Process name | Specific practices and requirements |

| Mixing concrete | A. The mixing and feeding of permeable concrete must be carried out strictly according to the mix ratio, and no mistakes are allowed. The first feeding must be weighed, and a reference mark can be made in the container feeding machine. B. Feeding order: first add aggregate, cement, and permeable concrete enhancer to the mixer and dry mix for 30 seconds, add 50% water and mix for 60 seconds, and then add the remaining water and mix for 120 seconds. C. Mixing time: from feeding and mixing to discharging, the 350-type mixer is 4 minutes under normal circumstances. The 500-type forced mixer is 3.5 minutes. |

| Finished material transportation | The mixed finished material should be transported to the construction site in time after leaving the machine, and it is advisable to transport it to the construction site within 40 minutes. The permeable concrete transportation must be covered with colored strips to maintain moisture, prevent moisture loss, and affect the construction quality. |

| Permeable pavement paving | A. The first is the continuous construction method. After pouring a single volume on the base layer, the surface layer is immediately spread. This construction method makes the base layer and the surface layer bond firmly and not prone to hollowing, but it is easy to crush the structural layer and cannot guarantee the strength of the base layer concrete. The base layer should be damaged as much as possible during construction. B. Another method is the interval construction method, that is, laying the base layer in the morning and constructing the surface layer in the afternoon. This method can ensure the strength of the structural layer concrete, with little impact from cross-construction, and can also reduce mixing machinery, machinery investment, and labor investment. However, when constructing the surface layer, the same grade of cement slurry must be used as the bonding layer when the surface of the base layer is fully watered and moistened to prevent hollowing. |

| Permeable pavement leveling | Permeable concrete should be leveled with a compactor or vibrated with a low-frequency flat vibrator and rolled with a special rolling tool. Compacting should be supplemented with manual filling and leveling. When leveling manually, the construction personnel should wear pressure relief shoes to operate. After the permeable concrete is compacted, it is advisable to use a trowel to finish the permeable concrete surface layer, and if necessary, it should be combined with manual compaction and leveling. During leveling, the top surface of the formwork must be kept clean, and the board surface at the joints should be flat. |

| Permeable pavement maintenance | A. After leveling and rolling, it should be smoothed with a concrete grinder in time. The edges and corners that cannot be polished by the surrounding grinder should be smoothed with artificial steel plates. The surface should be flat, the stones should be evenly distributed, there should be no lack of stones, and there should be no slurry accumulation. B. The maintenance work after the permeable concrete is cast is an important part of the permeable concrete construction process. Since inorganic binder materials are added to the permeable concrete, the early strength of the concrete increases rapidly, and the cement hardening will produce hydration heat, which requires sufficient water to cool down. C. Therefore, the method we adopt is full coverage protection with plastic film, that is, the plastic film around the surface layer should be larger than the surface layer by more than 50CM, and the overlap width of the plastic film should meet more than 30CM, and water should be sprinkled on the covered film to make the film evenly covered on the surface stones. It should be sealed and intact without leaving any gaps. D. The film must not be damaged. Local damage will directly lead to maintenance omissions and will cause the particles to fall off. The maintenance period of permeable concrete is two weeks. Watering maintenance must be guaranteed more than twice a day. The best maintenance effect is that there are a lot of dewdrops in the film floating on the surface of the surface stone. E. The film must be pressed firmly during maintenance to prevent the film from floating due to wind and to avoid partial damage to the permeable concrete due to improper maintenance. |

| Permeable pavement caulking | A. When the strength of permeable concrete reaches about 70% (2 weeks below 10℃ in winter, 10 days in spring and autumn, 2-5 days in summer), mechanical cutting can be carried out. The thickness of the mechanical cutting must meet the penetration of the surface layer thickness. After cutting the seam, the stone powder slurry in the seam must be washed with water in time to ensure that the seam is clean and dust-free, and the mud on the concrete surface caused by cutting the seam must be washed clean. B. When cutting the expansion joint, keep the seam of the base layer and the surface layer consistent from top to bottom, and do not stagger the seam. The setting of the single shrinkage joint area must first meet the design requirements, and secondly must be by the specifications of 25m~30㎡, and must not exceed 30㎡. It is best to control it within 25㎡. Too large an area will cause cracks in the concrete surface layer, and even hollowing. C. Expansion joints are filled with extruded boards, and contraction joints are filled with foam strips. When filling the joints, a 2~3MM height is reserved on the joint surface, and then structural glue is injected to seal. The width of the joints after caulking is consistent, the surface is flat, and the appearance is good. Therefore, the caulking material must have strong adhesion, good resilience, adapt to the expansion and contraction of concrete, and be insoluble in water, non-permeable, aging-resistant, non-flowing at high temperatures, and non-brittle at low temperatures. |

| Product protection | During the construction and maintenance of permeable concrete pavement, attention must be paid to the protection of finished products. People, animals, and vehicles should be strictly prohibited from walking on the road. Because it is difficult to repair, the surface is not easy to bond to the original level, so product protection must be insisted on until the completion acceptance and delivery for use. |

| Painting of pavement | The surface spray paint material is a special color topcoat for roads. This topcoat is bright in color, good in appearance, strong in UV resistance, and good in durability. The spraying machine is an airless sprayer. The paint consumption of light-colored pavement will be slightly larger. Because the light color has poor coverage, the material consumption is relatively large. When spraying paint, the surrounding materials of the previous process should be protected, and tape and other materials can be used to cover them. When mixing paint, the proportion should be uniform to prevent color difference, and the overlap should be consistent when spraying paint. |

Color Customization

Finished Product Maintenance

Selection of plastic film: Choose plastic film with good quality and high tensile strength to ensure that it is not easy to break when covering.

Laying of film: The surrounding plastic film should be more than 50CM larger than the surface layer, and the overlap width of the plastic film should be more than 20CM to ensure that the surface of the permeable concrete is fully covered.

Sprinkle water and moisten: Sprinkle water on the covered film to make the film evenly covered on the surface stones, so that it is airtight and intact without leaving gaps.

The film must not be damaged. Local damage directly leads to maintenance omissions and may cause stone falling. Therefore, the integrity of the film should be checked regularly, and if it is damaged, it should be repaired in time.

The maintenance cycle of the permeable concrete base is one week. Watering and maintenance must be guaranteed more than twice a day, which is indispensable (the number of watering should be increased depending on the temperature) to ensure that the cement is fully hydrated and avoid the surface stones from falling off due to lack of water.

The effect of maintenance is best when there are a large number of dewdrops floating on the surface of the surface stones in the film, which indicates that the cement hydration reaction of the permeable concrete is good.

The film must be pressed firmly during maintenance to prevent it from being blown away by the wind. At the same time, it is necessary to avoid damage to the local permeable concrete due to improper maintenance.