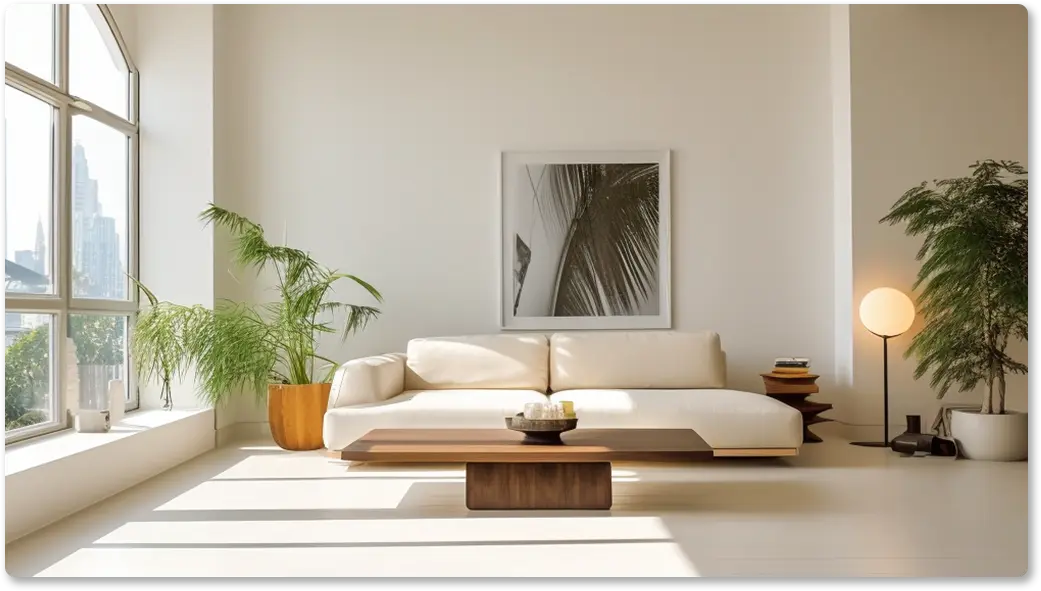

Interior wall latex paint

Product Application

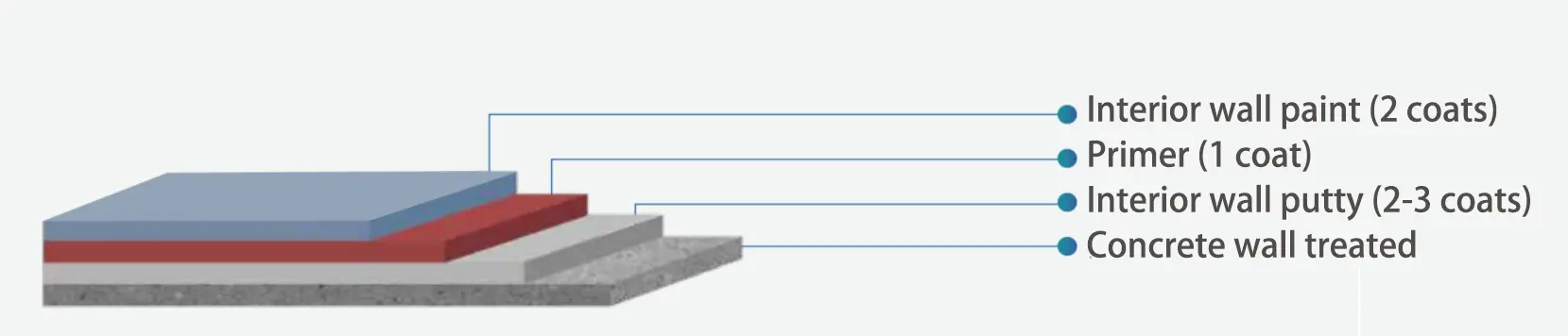

Interiro Wall Latex Paint Coating Structure

Construction Technology

| Construction sequence | Construction process | Optional materials | Material quantity | Construction method |

| 1 | Concrete wall | Sanding | ||

| 2 | Interior wall putty | KS-603 interior latex paint | Roll coating | |

| 3 | Primer | KS-603 interior latex paint | Roll coating | |

| 4 | Interior wall engineering paint | KS-603 interior latex paint | Roll coating |

| Process name | Specific practices and requirements |

| Base inspection | Use a ruler to check whether the wall surface meets the flatness requirements and whether the Yin and Yang corners are square. Remove the floating particles and residues on the surface to ensure that the surface is firm and free of loose objects, hollows, cracks, moisture, leakage, oil stains, obvious bumps, steel bars, nails, etc. |

| Base treatment | 1. Demolding ceiling: For demolding ceilings that have not been plastered, the template seams should be polished with a grinder first, and the template seams should be filled with putty first, and then the putty should be applied comprehensively after it is completely dry. 2. Other treatments: All-round filling treatment of fine cracks, small potholes, sand holes, and small damaged areas of the Yang corners. 3. Yin and Yang corner repair: Use a laser marking instrument to mark the vertical control line, measure the squareness of the Yin and Yang corners, and deal with unqualified ones. |

| Putty scraping | Scrape the first coat of putty, requiring the surface to be flat, without accumulation, and without missing scraping; after grinding and leveling, start scraping the second coat of putty, and grind it flat after the putty is completely dry. |

| Sanding and cleaning | 1. After the first coat of putty is completely dry, polish it. First, use the polishing equipment to polish the entire wall and ceiling, and then polish it with sandpaper. You can use the sun lamp to illuminate from different angles to check the smoothness of the wall. After the second coat of putty is completely dry, polish it manually. 2. After polishing, use a feather duster or air gun to remove the floating dust; the putty is polished flat and smooth, which can save the amount of topcoat accordingly. 3. Finished products such as doors, windows, vents, skirtings, switches, and sockets should be protected to prevent pollution. 4. Finally, check the polishing flatness again to check whether there are omissions or incomplete polishing, and ensure that the primer is applied in accordance with the quality standards. |

| Apply alkali-resistant primer | After the putty is polished and smooth, it is necessary to apply an alkali-resistant primer before painting to avoid alkalis on the wall. |

| Inspection and putty filling | After the anti-alkali primer is completely dry, use a sun lamp to check to ensure uniformity, no dripping, and no omissions. Use putty to repair sand holes, grooves, local unevenness and defects, and polish with fine sandpaper. Remove the floating dust on the surface and then apply primer. |

| Apply top coat | 1. The first coat of topcoat should be diluted strictly according to the product instructions, fully stirred, and uniform. 2. Roll from the ceiling to the wall. Roll back and forth several times when rolling. Finally, roll gently and keep the speed and strength consistent to ensure quality and effect. 3. Before applying the second coat of topcoat, conduct a comprehensive inspection. If any defective parts are found, fill them with putty, polish them after drying, and apply primer. The second coat of topcoat has the same requirements as the first one. 4. When you need to do color separation, you must wait until the previous color is dry before applying another color, and paste the color separation paper to prevent contamination of the previous color. |

| Sanitary cleaning | Clean up splashed materials, dust, and debris, remove obstructions, etc., and make sure the site is clean after work. |

| Completion acceptance | After completion, check whether the surface flatness, verticality, appearance, and other qualities meet the requirements. (Surface flatness 2MM, Yin and Yang corners vertical 2MM, Yin and Yang corners square 2MM, vertical facade 3MM). |

Finished Product Maintenance

·During the construction period, construction workers should ensure adequate sleep to ensure that they are focused during high-altitude operations and avoid accidents.

·Before construction, check whether the scaffolding and the frame are firmly erected. Only start the operation after ensuring safety and reliability.

·It is forbidden to wear slippers, shoes with smooth bottoms, and high heels when working on the scaffolding.

·Smoke and fireworks are strictly prohibited in places where solvent-based paints and thinners are stored and used.

·Equip with necessary protective glasses and protective masks.

·Construction and lighting electrical appliances must be installed and wired by electrical safety regulations. It is strictly forbidden to pull wires and wire them at will.

·Provide safety education to all on-site staff.