Hard acrylic court

Product Application

Hard acrylic courts apply in places such as tennis, volleyball, badminton, and basketball courts.

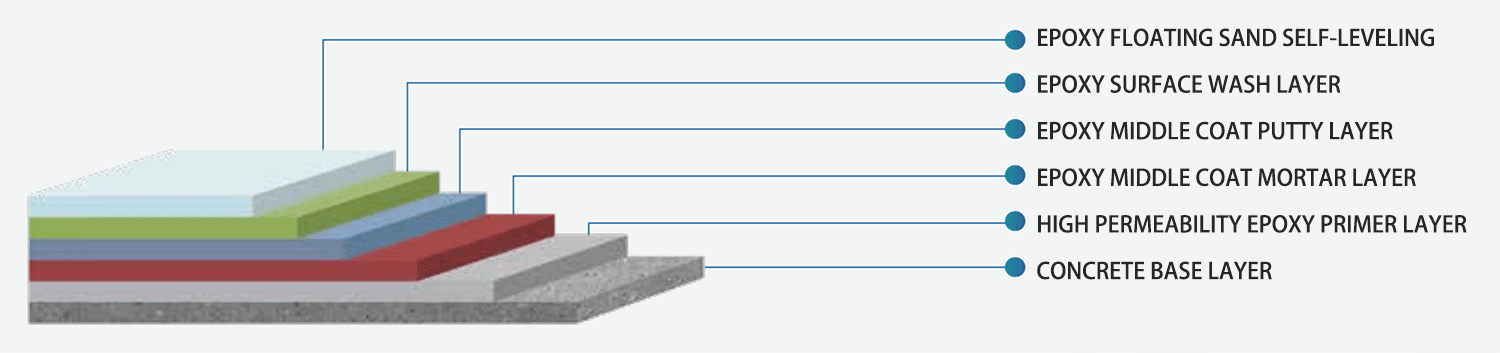

Hard Acrylic Courts Coating Structure

Construction Technology

| Process Name | Specific methods and requirements |

| Surface treatment | The cement floor foundation is fully polished with a water grinder and cleaned after it is completely polished. |

| Base surface pickling | First, wet the ground with clean water, then pickle the ground with dilute hydrochloric acid of about 5-8% concentration, then wash it with clean water, and dry it in the sun until it is dry enough before the acrylic surface layer construction process can be carried out. |

| Primer layer | 1. Materials: acrylic court AB primer, water.

2. Ratio: primer A: primer B: water = 1:1:3. 3. Construction: Mix various materials in proportion, stir evenly with an electric mixer, and roll the slurry evenly on the cement floor with a roller until it is shiny. The loose parts can be rolled one or two times. Note: The primer must first mix the A and B components evenly, then add water and stir evenly before use. |

| Middle coating | 1. Materials: acrylic court special middle coating, quartz sand (80 mesh, 120 mesh), water;

2. Ratio: acrylic court special middle coating, quartz sand (80 mesh, 120 mesh): water = 1KG: 1KG: 0.2KG 3. Construction: After the primer coating is cured, mix the various materials in proportion, stir evenly with an electric mixer, pour into the construction site, and use a special acrylic scraper to scrape the mixed slurry evenly on the cement floor in two times. Use 80 mesh coarse sand for the first middle coating and 120 mesh fine sand for the second middle coating. |

| Topcoat layer | 1. Materials: Colored acrylic court topcoat, quartz sand (120 mesh), water;

2. Ratio: (1) First coat: acrylic court topcoat: quartz sand (120 mesh): water = 1KG: 0.3KG: 0.1KG (2) Second coat: acrylic court topcoat: water = 1KG: 0.1KG 3. Construction: Mix evenly with an electric mixer, pour into the construction site, and directly scrape or roll the wall, it is best to scrape the wall and roll it once with a short wool roller, the effect is ideal. Note: Add quartz sand to the first coat of topcoat, and do not add quartz sand to the second coat of topcoat. |

| Marking | 1. Material: acrylic polyurethane marking paint. Material characteristics: wear-resistant, no discoloration, strong adhesion. 2. Construction: Measure and position according to the standard size, mark the line position with canvas line, then stick masking paper along the canvas line on the court, use a brush to evenly apply acrylic special marking paint between the two masking papers, and tear off the masking paper after the paint is dry. |

| Product Performance | |

| High-Performance Sports Paint | Acrylic is a high-performance sports paint that is used in sports fields and entertainment venues. It has unparalleled performance, wear resistance, and vivid and lasting colors. |

| Sports performance | Excellent performance is the key to high-quality product performance, and this is exactly what Jinshite materials bring you. Our sports field surface ensures the comfort of players' feet and the consistent rebound effect of the ball. You can even feel the grass court. The different speeds brought by the medium-speed court and the hard court. |

| Fade resistance | Kingstone provides you with personalized color choices, making your choice truly unrestrained. The same fading design means that you don't need to replace the surface due to fading for many years. Because the pigment is added with special enhancers, the color effect is guaranteed, giving you the deepest and fullest visual enjoyment. |

| Abrasion resistance | 100% pure acrylic acid is added with hydroxypropyl methylcellulose, which is revolutionary and epoch-making, which is our guarantee for you to enjoy the fun of sports in the future. It is precisely because of the outstanding performance of this fiber that the venues paved by Kingstone materials often appear in various competitions. |

Color Customization

Finished Product Maintenance

1. The venue needs to be cleaned frequently. Severely polluted areas can be brushed or scrubbed with detergent in moderation.

2. Flush with water before and after the game to maintain the color and hygiene of the venue. In hot summer weather, spray cool water to reduce the surface temperature.

3. If the venue is broken or delaminated, it should be repaired in time according to the specifications to prevent it from spreading. Water should be sprinkled frequently around the venue to effectively prevent dust from flying and affecting the cleanliness of the venue.

4. The sewers should be cleaned frequently to keep the drainage in the venue unobstructed.

5. Those entering the venue must wear sports shoes, and the studs cannot exceed 7 mm.

6. Avoid long-term heavy pressure and prevent severe mechanical impact and friction.

It is prohibited for all kinds of motor vehicles to drive on it, and it is prohibited to bring explosive, flammable, corrosive and harmful substances into the venue.