Exterior wall latex paint

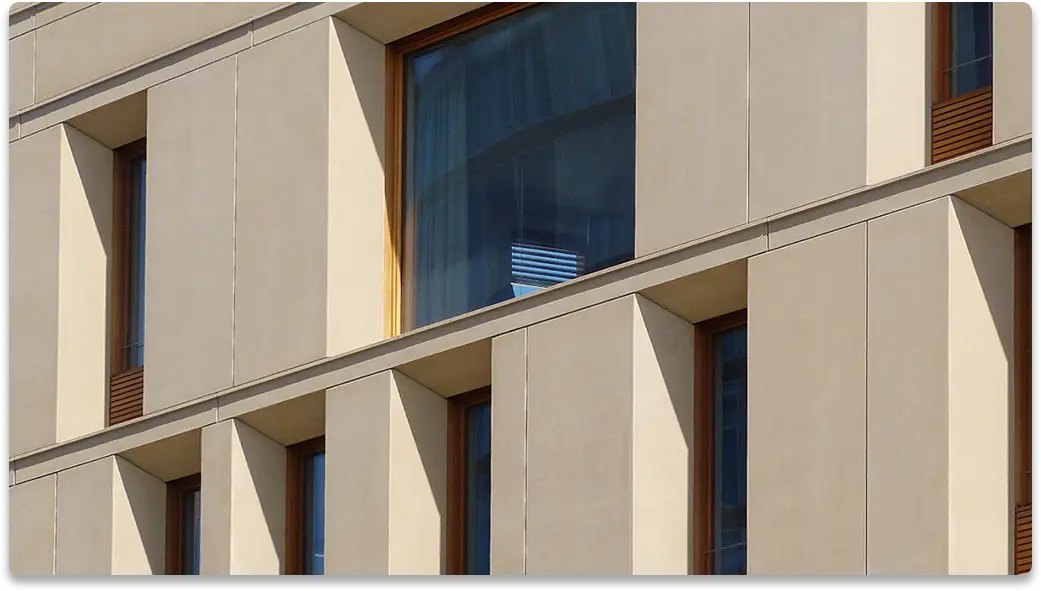

Product Application

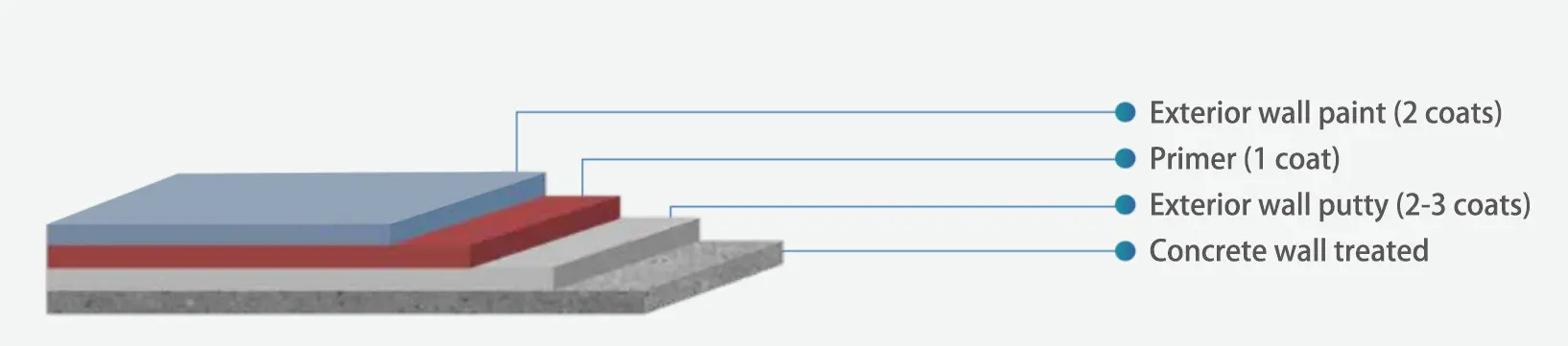

Exterior Wall Latex Paint Coating Structure

Construction Technology

| Construction sequence | Construction process | Optional materials | Material quantity | Construction method |

| 1 | Concrete wall | Sanding | ||

| 2 | Exterior wall putty | KS-602 exterior latex paint |

Roll coating | |

| 3 | Primer | KS-602 exterior latex paint |

Roll coating | |

| 4 | Exterior wall engineering paint | KS-602 exterior latex paint | Roll coating |

| Process name | Specific practices and requirements |

| Clean the wall | Remove the residual slurry and unstable attachments on the wall, and use a spatula to scrape the wall, especially the corners of the window frame. |

| Protect | Protect the finished and semi-finished products of the door and window frames, glass curtain walls, and parts that do not require construction before construction to avoid pollution. |

| Putty repair | This is the key to the base treatment. At present, we often use waterproof putty or flexible putty for exterior walls. |

| Sandpaper polishing | When sanding with sandpaper, it is mainly to sand the joints of the patch putty. Pay attention to the technique when sanding and follow the operating specifications. Use water sandpaper for sandpaper and 80 or 120 mesh water sandpaper for polishing the putty layer. |

| Local putty repair | After the base is dry, use putty to fill the uneven places and sand it flat after drying. The finished putty should be stirred before use. If the putty is too thick, add water to adjust it as appropriate. |

| Full putty scraping | Place the putty on the tray and scrape it with a trowel or rubber scraper, first up and then down. Scrape 2-3 times of putty according to the base condition and decoration requirements, and each layer of putty should not be too thick. After the putty is dry, it should be sanded with sandpaper in time. It should not be wavy or leave marks. After sanding, sweep away the floating dust. |

| Base coating application | Use a roller or a brush to apply evenly. Be careful not to miss any spots or apply too thickly. |

| Post-priming repair | After the anti-alkali sealing primer dries, some fine cracks and other defects on the wall will be exposed due to the good permeability of the anti-alkali sealing primer. At this time, acrylic putty can be used for repair. After drying and sanding, apply the anti-alkali sealing primer again to prevent the absorption effect of the opposite coating from being inconsistent due to the previous repair, thus affecting its final effect. |

| Top coating application | After opening the barrel of the topcoat, stir it evenly, and then dilute and stir it evenly according to the proportion required by the product manual. When the wall needs to be separated, first use a powder line bag or ink fountain to pop out the separation line, and leave 1-2CM of room at the intersection of colors when brushing. One person first uses a roller brush to apply the paint evenly, and the other person then uses a brush to flatten the paint marks and splashes (spraying construction method can also be used). Bottom penetration and dripping should be prevented. Each surface should be painted from the edge to the other side, and should be completed in one go to avoid joint marks. After the first coat is completely dry, apply the second coat of paint. Generally, 2-3 coats are required, depending on the situation. |

Finished Product Maintenance

·During the construction period, construction workers should ensure adequate sleep to ensure that they are focused during high-altitude operations and avoid accidents.

·Before construction, check whether the scaffolding and the frame are firmly erected. Only start the operation after ensuring safety and reliability.

·It is forbidden to wear slippers, shoes with smooth bottoms, and high heels when working on the scaffolding.

·Smoke and fireworks are strictly prohibited in places where solvent-based paints and thinners are stored and used.

·Equip with necessary protective glasses and protective masks.

·Construction and lighting electrical appliances must be installed and wired by electrical safety regulations. It is strictly forbidden to pull wires and wire them at will.

·Provide safety education to all on-site staff.