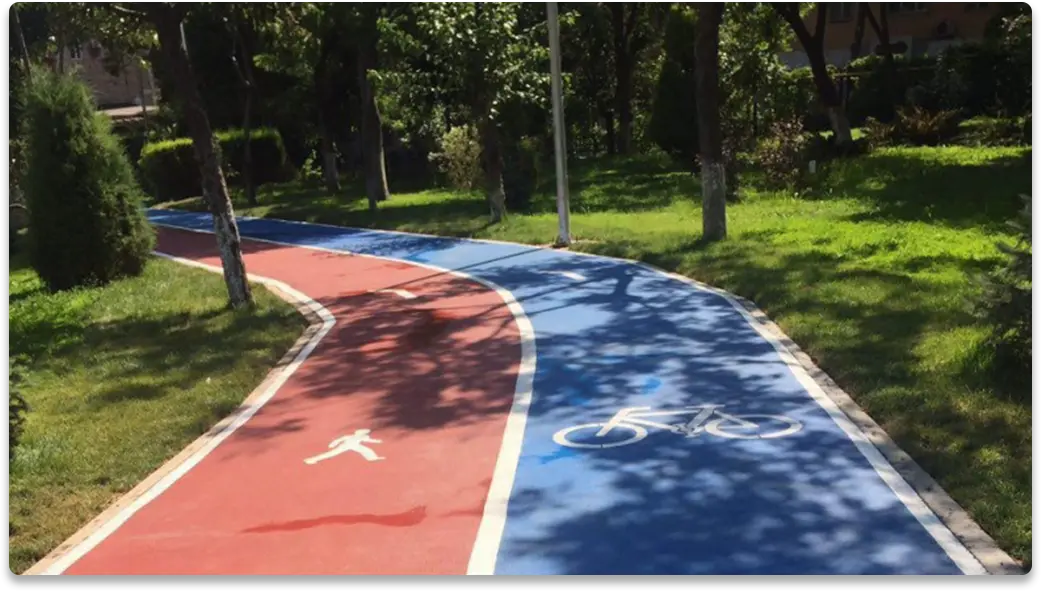

EPDM rubber particle runway

Product Application

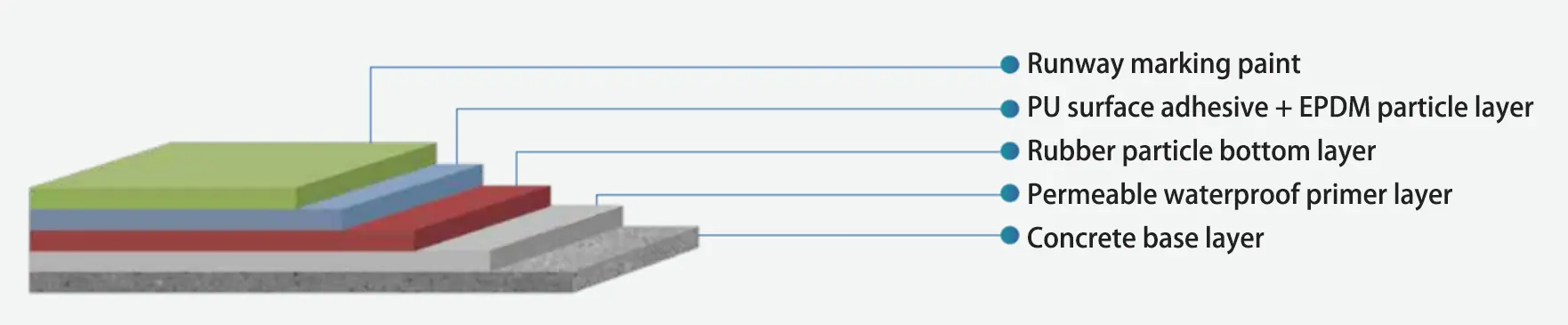

EPDM Rubber Particle Runway Coating Structure

Construction Technology

| Process name | Specific practices and requirements |

| Base surface treatment | The first step in the construction of the plastic track is to clean the ground to be constructed as a whole and remove dust and dirt, which takes a long time. Therefore, secondary dust generation should be prevented during the cleaning process. After cleaning, find a flat base and grind the ground flat to facilitate the subsequent waterproof primer construction. |

| Measurement and marking of the bottom line | To reasonably arrange the paving workload, it is necessary to first measure and draw the boundary line on the foundation according to the set plan, divide the entire site into strips and blocks, and then pave in strips and blocks. |

| Base brushing | After the foundation is qualified, to strengthen the adhesion between it and the surface material, first scrape a layer of special glue and diluent mixed in a certain proportion on the foundation, apply the glue evenly with a roller brush, and start paving the bottom black particles after drying. |

| Base layer paving | Use black rubber particles and special glue in a weight ratio of 6.5:1, stir evenly in the mixing area with a stirring device, send it to the pre-marked boundary with a feeding car, spread it with a scraper, and compact it with a roller. After the bottom layer is solidified, start paving the surface layer. After curing for two to three hours, compact it with a roller again, and smooth the uneven places with a trowel. If the trowel and roller stick to the particles, add a little thinner to smooth it. |

| Surface layer paving | Use EPDM particles and special glue in a weight ratio of 5:1, stir evenly in the mixing area with a stirring device, send it to the pre-marked boundary with a feeding car, spread it with a scraper, and compact it with a roller. Pay attention to density, flatness, and thickness, and roll it repeatedly. After curing for two to three hours, compact it with a roller again, and smooth the uneven places with a trowel. If the trowel and roller stick to the particles, apply a little thinner to smooth it. |

| Measurement and marking of marking line | Mark the court markings as required. After marking, it needs to be reviewed by sports technicians. The straight part is reviewed with a certified steel tape measure. Only after confirming that it meets the standards can it be painted according to the specified signs. |

| Later maintenance | After the construction is completed, the runway needs maintenance. This includes rain protection, sun protection, cold protection, etc. Before using the runway, make sure the surface layer is completely dry, avoid using it in a humid environment, and do a good job of cleaning to prevent contamination by impurities. |

| Features | Specific features |

| Features | With appropriate elasticity, it can generate appropriate rebound force during activities, protect joints and ligaments, and reduce the risk of injury. |

| Protection | The special anti-skid layer can ensure that the surface is non-slip, and it can ensure that the feet are firm even in wet conditions and bad weather, and run fast and safely. |

| Wear-resistant | Excellent wear resistance can ensure the long-term stability of the pavement structure. |

| Stable | Excellent anti-aging and acid rain, heat and humidity, ozone, and ultraviolet resistance ensure that the physical properties and appearance structure of the pavement remain unchanged. |

| Practicality | All-weather use with an appropriate drainage system, even after heavy rain or flushing, can be used for training, competition, and games immediately without performance changes. |

| Easy maintenance | No special maintenance is required within its reasonable use range, but daily cleaning and flushing are necessary. |

| Beautiful colors | Specialized EPDM particles, soft surface color, and granular surface prevent the reflection of dazzling light, are beautiful and durable, and can be matched with multiple colors. |

| Scope of application | It is suitable for kindergartens, schools of all levels and types, professional stadiums, athletic tracks, semicircular areas; national fitness paths, indoor gymnasium training tracks, playground road pavements, indoor and outdoor roads, tennis, basketball, volleyball, badminton, handball venues; parks, residential areas, and other activity venues. |

Finished Product Maintenance

·The venue needs to be cleaned frequently. Severely polluted areas can be brushed or scrubbed with detergent in moderation.

·Water should be used to flush the venue before and after the game to maintain the color and hygiene of the venue. In hot summer weather, cool water should be sprayed to reduce the surface temperature.

·If the venue is broken or delaminated, it should be repaired in time according to the specifications to prevent it from spreading. Water should be sprinkled frequently around the venue to effectively prevent dust from flying and affecting the cleanliness of the venue.

·The sewer should be cleaned frequently to keep the drainage in the venue unobstructed.

·Those entering the venue must wear sports shoes, and the studs cannot exceed 7 mm.

·Avoid long-term heavy pressure and prevent severe mechanical impact and friction.

·All kinds of motor vehicles are prohibited from driving on it, and it is prohibited to bring explosive, flammable, corrosive, and harmful substances into the venue.