Environmentally friendly polyurethane plastic runway

Product Application

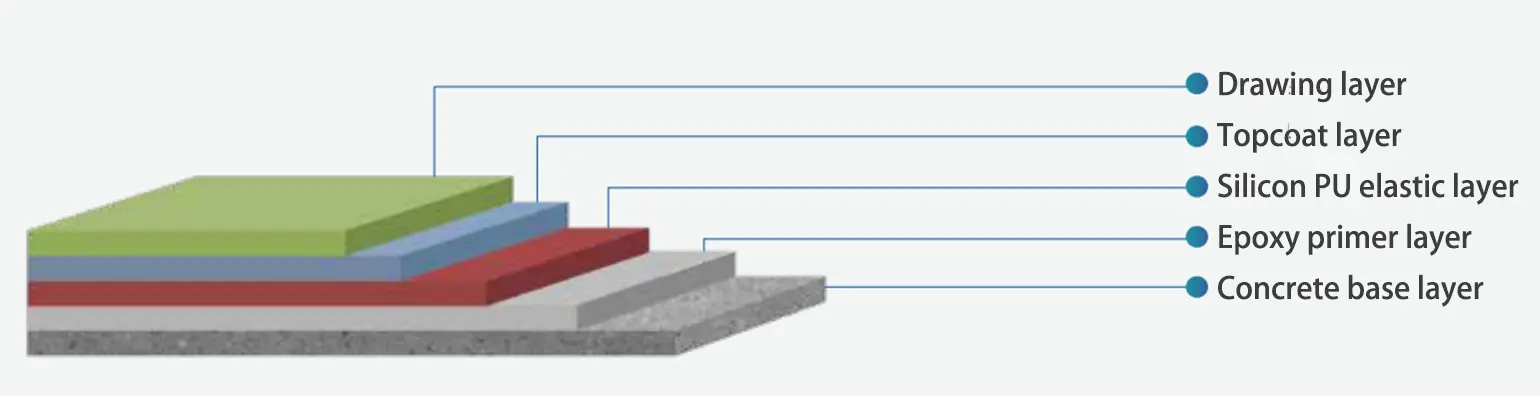

Environmentally Friendly Polyurethane Plastic Runway Coating Structure

Construction Technology

| Product features | Specific features |

| Super strong characteristics, excellent performance | Even ball rebound, sports cushioning, and shock absorption, excellent anti-slip start, and safe and fast movement. |

| Breakthrough tradition, simple construction | Silicon PU can be laid directly on new and old cement floors, breaking through the traditional construction characteristics and overwhelmingly surpassing general floor materials. It is easy to construct, does not require special maintenance, and is easy to clean. It is an epoch-making new elastic court material. |

| Excellent quality, environmentally friendly, and economical | Silicon PU is a single-component PU material, water is a curing agent, and no harmful chemical components will remain. It is a truly environmentally friendly court material. All product indicators meet the national indoor decoration hygiene standards. |

| Scope of application | Applicable to all kinds of indoor and outdoor courts such as basketball, tennis, badminton, table tennis, volleyball, handball, indoor small football fields, various fitness rooms, activity rooms, various sports venues and kindergartens, hospitals, hotels, and other venues. |

| Service life | About 8 years. |

| Process name | Specific practices and requirements |

| Base surface treatment | The first step in the construction of a plastic track is to clean the ground to be constructed as a whole and to remove dust and dirt from the dust which takes up a lot of time. Therefore, it is necessary to prevent the secondary generation of dust during the cleaning process. After cleaning, find a flat base and grind the ground flat to facilitate the application of waterproof primer. |

| Waterproof base layer | If it is an old cement foundation, there is damage, moss, convex marks, etc., and the ground should be lightly ground with a sand grinder to clean the ground; if it is a new cement foundation, it should be maintained and cleaned, or the site can be rinsed with diluted hydrochloric acid or oxalic acid to see the effect of the foundation maintenance. After the site is dry, use a roller to apply the waterproof primer to the ground twice and check carefully. There should be no places that are not painted densely. |

| Silicon PU elastic layer | The silicon PU elastic layer is a single component. Before the elastic layer is constructed, it should be carefully checked to confirm that the foundation treatment is complete before the elastic layer construction can be carried out. Stir the silicon PU elastic material evenly at high speed, and directly apply the material to the base surface in layers with a rubber sheet. The amount of material to be laid should be calculated during construction. The stirred and unpacked materials should be laid quickly, otherwise the materials will solidify and waste. The time interval between each layer of application is based on the drying time of the previous layer. The specific drying time depends on the weather conditions on-site. The thickness of each layer is recommended to be about 1-1.5MM until the required thickness is reached. Pay attention to the leveling effect when applying to ensure the surface is flat. Avoid construction under the scorching sun and high temperatures. After the elastic layer is dry, use the water accumulation method to test the surface flatness. |

| Silicon PU topcoat | When applying the silicon PU water-based topcoat, stir the color paste and curing agent evenly according to the ratio, and apply it to the surface of the elastic layer in three times with a spray gun or roller. If the friction coefficient of the surface needs to be adjusted, you can add special quartz sand for the surface layer and mix it evenly before applying. The surface layer construction materials must be sufficient, otherwise it will directly affect the use effect and service life. Avoid construction under the scorching sun and high surface temperature to ensure the surface effect. |

| Court marking | Measure and position according to the standard size, mark the boundary position, stick masking tape on both sides of the boundary on the court, and apply special marking paint between the masking tape in two coats. If the surface of the court is rough, add a little special surface sand in the first coat to prevent edge seepage. Because our company's marking material is water-based aliphatic marking paint (no fading or yellowing, full texture), wait for the surface to dry before tearing off the masking tape after painting. |

Color Customization

Finished Product Maintenance

·The venue needs to be cleaned frequently. Severely polluted areas can be brushed or scrubbed with detergent in moderation.

·Water should be used to flush the venue before and after the game to maintain the color and hygiene of the venue. In hot summer weather, cool water should be sprayed to reduce the surface temperature.

·If the venue is broken or delaminated, it should be repaired in time according to the specifications to prevent it from spreading. Water should be sprinkled frequently around the venue to effectively prevent dust from flying and affecting the cleanliness of the venue.

·The sewer should be cleaned frequently to keep the drainage in the venue unobstructed.

·Those entering the venue must wear sports shoes, and the studs cannot exceed 7 mm.

·Avoid long-term heavy pressure and prevent severe mechanical impact and friction.

·All kinds of motor vehicles are prohibited from driving on it, and it is prohibited to bring explosive, flammable, corrosive, and harmful substances into the venue.