Elastic acrylic runway

Product Application

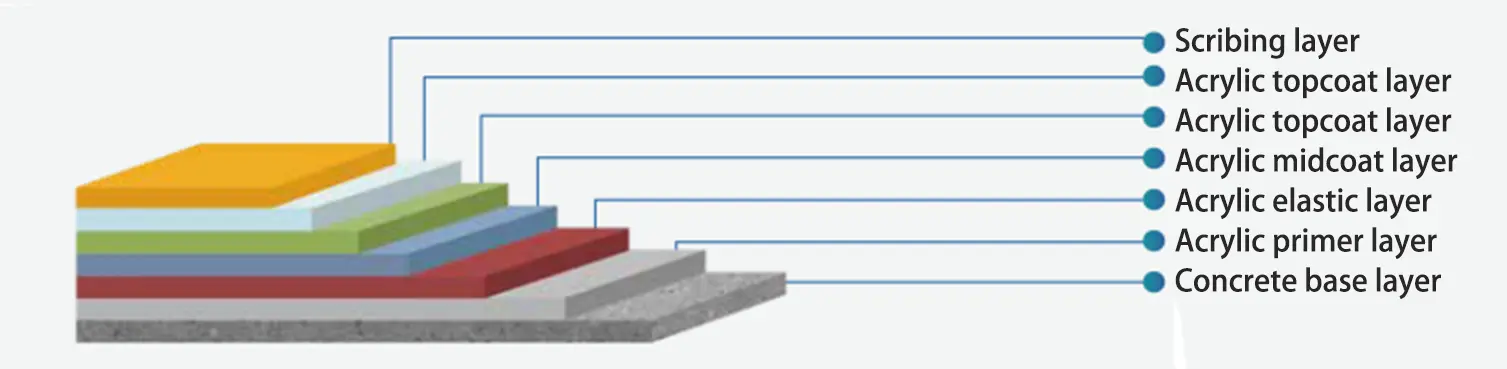

Elastic Acrylic Runway Coating Structure

Construction Technology

| Process name | Specific practices and requirements |

| Basic inspection and treatment | Check the flatness, density, and slope of the foundation. Remove the dirt and debris from the foundation surface and the surrounding gaps. Remove the dirt and oil stains on the foundation surface. Use a machine to grind the individual super-high parts of the foundation flat, and repair and level the local sunken parts of the foundation. If it is an old site renovation, the damaged surface layer must be completely removed after entering the site, and then repaired with similar materials. Make a V-shaped groove at the cracks, then pour special repair glue to reinforce and level. |

| Pickling or grinding | Wet the ground with clean water, clean the ground with about 8% dilute hydrochloric acid, and then rinse it with cleaning water. |

| Primer coating | Roll the primer evenly on the base surface. The amount depends on the firmness of the site. The general amount is about 0.078KG/M. After it is dry, you can proceed to the next step of construction. |

| Seam filling | After the primer is cured, use compressible foam to gently squeeze it into the temperature seam. Make sure that the temperature seam is sealed and filled without protrusion; stir the caulking glue in proportion and scrape it into the seam two to three times. |

| Water filling | Mix cement leveling agent with 80-100 mesh sand (1:1) and stir evenly to level the waterlogged area. After leveling, the waterlogging should not exceed 3MM within 30 minutes after rain to be qualified. |

| Apply leveling layer | After mixing cement leveling agent with 80-100 mesh sand (1:1) thoroughly, use a scraper to scrape a piece of the whole site. |

| Apply elastic layer | Elastic material: No. 325 cement = 25:1.5 (water can be added to adjust the construction consistency), use a flat scraper to scrape on the base surface, the thickness of each scraping should not exceed 1-2MM, and the time interval between each scraping: the previous one is dry (generally about 8 hours, depending on the weather conditions on site), until the required thickness is scraped. After the elastic layer is dry, use a machine to trim the rough surface part, and then apply the reinforcement layer. |

| Apply leveling layer | Use cement leveling agent: sand = 1:0.5-0.8 (water can be added to adjust the construction consistency), scrape with a flat scraper, and the surface after scraping is required to be flat and smooth. |

| Apply surface layer | Acrylic topcoat: quartz sand = 1:0.8 (water can be added to adjust the construction consistency), use a flat scraper to scrape the first coat; after the first coat of topcoat is dry, use a roller to roll the second coat of topcoat, with an appropriate amount of water (without adding quartz sand). |

| Marking | Measure and position according to the standard size, mark the line position with canvas line, then use masking paper to stick on the court along the canvas line, and then use a brush to evenly spread the marking paint between the two masking papers. When the paint surface is afternoon, tear off the masking paper. |

| Performance name | Specific performance |

| Surface layer | Jinshi Special Line Paint is a pure acrylic emulsion paint designed for the line surface of acrylic courts. It has a saturated color and is generally white and yellow. Other colors can be customized as needed. |

| Texture layer | One or two layers of Jinshi Special colored acrylic without sand are used to form a wear-resistant, all-weather, and UV-resistant coating. |

| Reinforcement layer | It adopts a two-layer design with a waterproof function and is applied to cement concrete foundations and asphalt concrete foundations. |

| Service life | 5-8 years. |

| Elastic layer | Jinshi Special water-based elastic material, which is formulated by combining acrylic latex and special grade rubber particles, increases the absorption of impact force, provides better comfort for athletes, and maximizes the toughness of the court surface. |

| Primer emulsion | Jinshi Special acrylic primer emulsion is a high-viscosity acrylic emulsion used for the base surface. |

| Scope of application | Indoor and outdoor basketball courts, tennis courts, badminton courts, volleyball courts, other sports grounds, school playgrounds, pedestrian walkways, sports stands, kindergarten floors, kindergarten painting walls, bicycle greenways, roller skating grounds, etc. |

Finished Product Maintenance

·The venue needs to be cleaned frequently. Severely polluted areas can be brushed or scrubbed with detergent in moderation.

·Water should be used to flush the venue before and after the game to maintain the color and hygiene of the venue. In hot summer weather, cool water should be sprayed to reduce the surface temperature.

·If the venue is broken or delaminated, it should be repaired in time according to the specifications to prevent it from spreading. Water should be sprinkled frequently around the venue to effectively prevent dust from flying and affecting the cleanliness of the venue.

·The sewer should be cleaned frequently to keep the drainage in the venue unobstructed.

·Those entering the venue must wear sports shoes, and the studs cannot exceed 7 mm.

·Avoid long-term heavy pressure and prevent severe mechanical impact and friction.

·All kinds of motor vehicles are prohibited from driving on it, and it is prohibited to bring explosive, flammable, corrosive, and harmful substances into the venue.