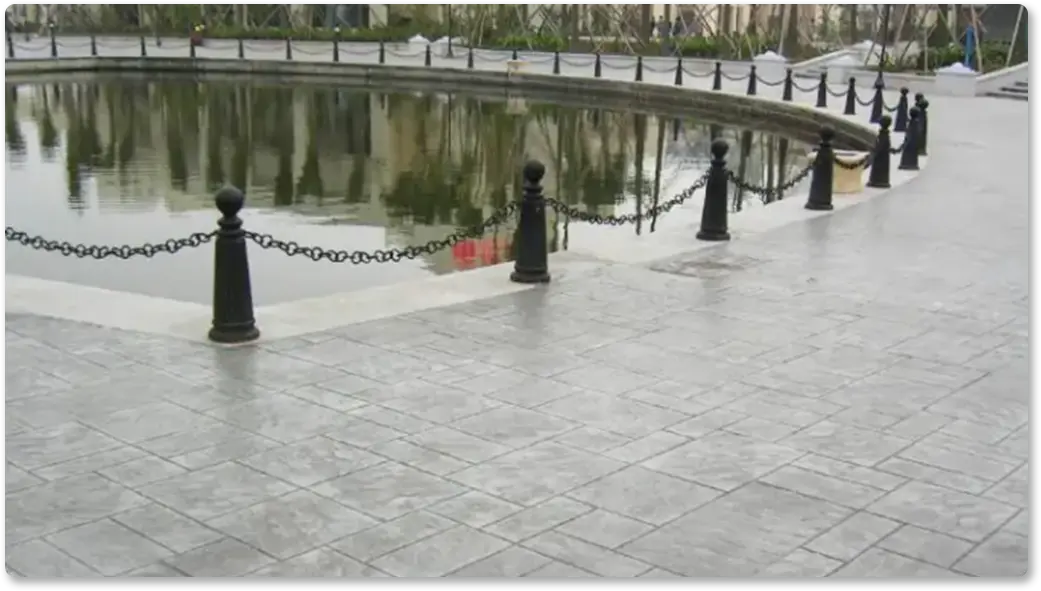

Concrete film pressing protective agent

Details

| How to use |

| 1. Before construction, grind the concrete surface to make it smooth (grind to about 400#), dry it, and clean it. |

| 2. Protect the non-treated parts of the concrete. |

| 3. Spray or roll the protective agent evenly on the surface of the concrete to be treated, and apply it in a criss-cross manner without missing any. |

| 4. After the concrete is treated with the protective agent, it can enter the next construction process (such as polishing with a polishing agent) after natural drying for 24 hours. Before it is put into use, it is best to naturally cure it for more than 48 hours. |

Construction name

|

Product advantages |

| Wear-resistant and anti-slip |

The texture of the pressed floor is different in-depth and staggered. Some models of molds have a pockmarked effect, which greatly improves the anti-slip effect. Authoritative testing shows that it is durable and wear-resistant, and prevents weathering and peeling. |

| Refuse to crack |

Use inorganic colorants and UV-resistant concrete sealing protective agents to interact with each other, the color is stable, does not fade, is not afraid of chemical corrosion, and adapts to drastic temperature changes. |

One-piece molding

|

The texture of the cast-in-place colored stamped floor is integrated with the base layer, which solves the problem of loose surface and easy cracking caused by hollowness that is difficult to overcome in conventional paving, thus extending the service life of the floor. |

| Three-dimensional effect |

Rich patterns, multiple combinations, realistic effects, highlighting personality, colorful, nostalgic or classical, romantic or modern, three-dimensional highlighting. |