Ceramic particle non-slip pavement

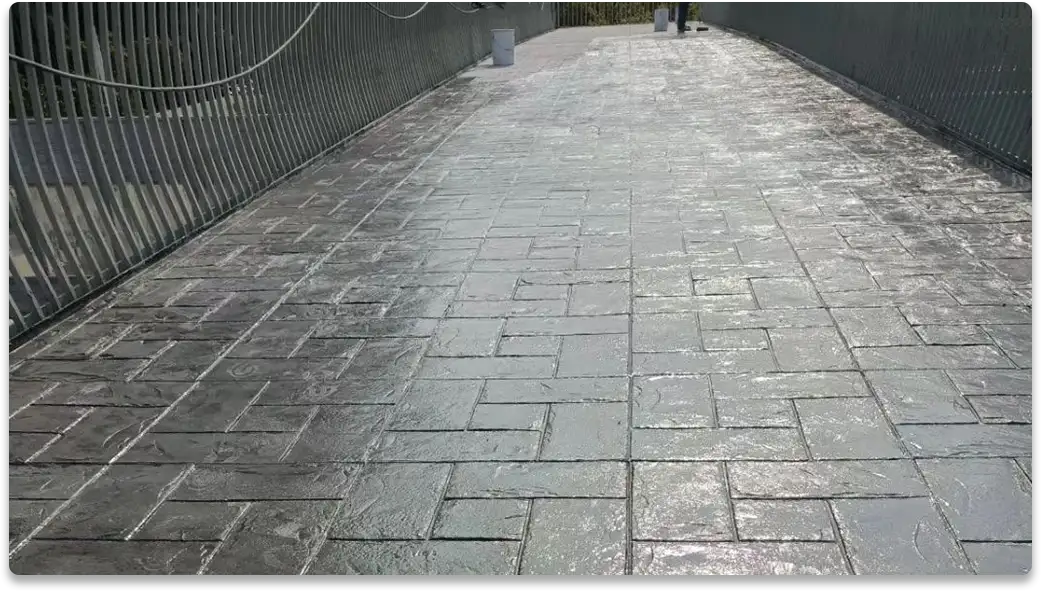

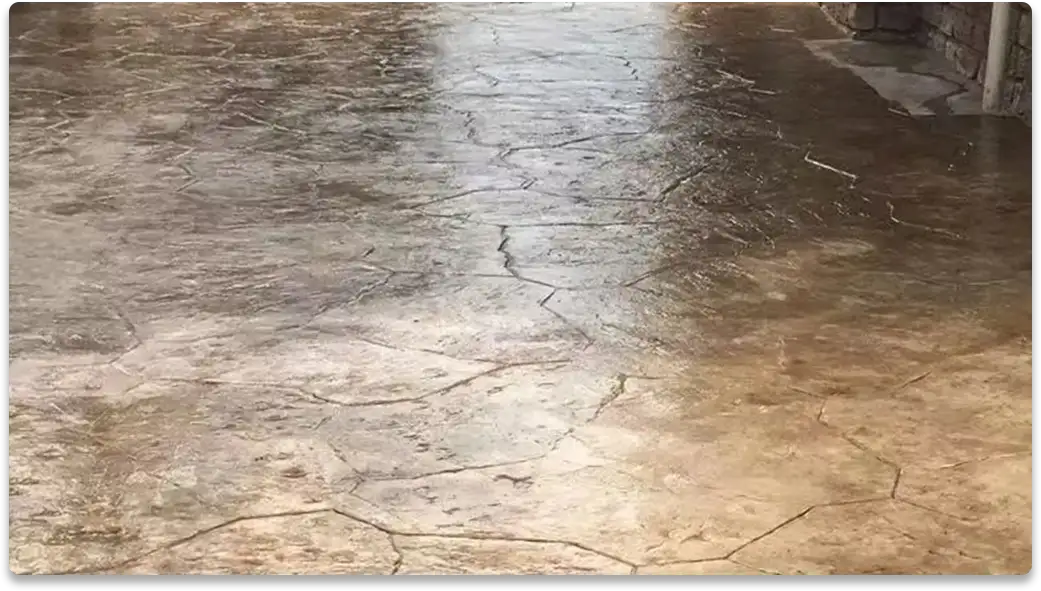

Product Application

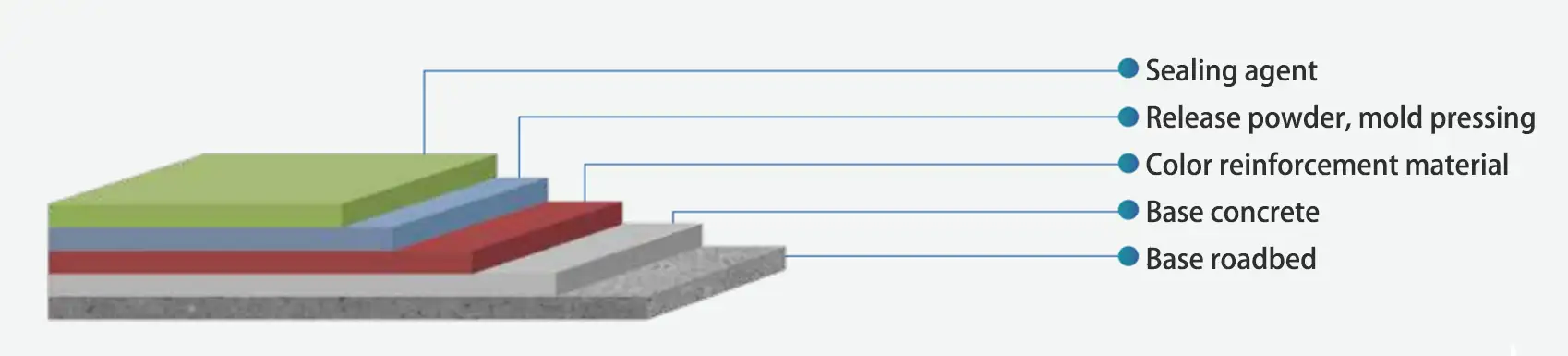

Ceramic Particle Non-slip Pavement Coating Structure

Construction Technology

| Construction sequence | Construction process | Optional materials | Material quantity | Construction method |

| 1 | Subgrade | Grinding | ||

| 2 | Base Concrete | Concrete pouring and leveling of the base layer | Pouring, smoothing | |

| 3 | Colored reinforced material | KS-402-1 strengthening powder | Spraying | |

| 4 | Molding | Printing | ||

| 5 | Spray sealant | KS-402-2 sealant | Spraying |

| Process name | Specific practices and requirements |

| Formwork for the working surface | The construction personnel must first carry out the work of separating and regional formwork according to the design requirements. During the formwork, attention must be paid to the height, verticality, flooding slope, and other issues. |

| Pouring of base concrete | Strictly prepare and deliver to the site according to the designed concrete strength. Spread flat as required. Raise the slurry of the paved base concrete (note: the slurry must be fully raised) and then use a special large scraper or hand scraper to smooth and remove the excess moisture on the surface of the concrete. After the excess moisture on the surface of the base concrete is removed, use a large trowel to smooth it. |

| Spreading of strengthening agent | After the concrete absorbs water until there is no obvious watermark on the surface, grasp the degree of solidification of the concrete according to the weather conditions, spread the first coat of strengthener, and use a manual iron trowel to level and finish after the strengthener absorbs water, and complete the first coat of powdering. After the strengthener is moistened to a certain extent, spread the second coat of the strengthener according to the color depth or moistening. The usage is 3KG/M. When using 2 or more colors, isolation measures should be taken at the junction of the colors to ensure that there is no color bleeding. |

| Finishing and finishing | According to the hardening degree of the hardener, it should be smoothed with a trowel at least three times, and the finishing operation should be carried out alternately. The smoothing should be done lightly, and it should not be too hard to avoid bringing the base color of the base. In places where there is no hardener or the color is lighter, use the remaining 1/3 of the hardener to fill and finish. |

| Spreading of release agent | When the surface of the hardener is dry and free of moisture, a slight fingermark can be formed by pressing the surface of the hardener with your fingers, and evenly spreading a layer of release agent that matches the hardener. The release agent should not be too much, just spread it evenly. |

| Pressure molding | After the molding agent is spread while ensuring that the concrete surface can bear the weight of a person, the pattern is pressed with a pre-made mold depending on the size of the construction area, the initial setting condition of the base concrete, the weather conditions, sunshine, temperature, wind force, and other factors. According to the design requirements, lay the mold along the reference line of the layout pattern, starting from one edge, lay the first mold, place the second mold close to the edge of the first mold, and so on. Then use manpower to make the mold press down the concrete vertically to form a texture on the concrete surface. Repeat the above operations in an orderly manner until the die-pressing process is completed. |

| Cutting of expansion joints | After the die pressing is completed, the concrete is cured by relying on the moisture in the dry-spreading material and its sealing effect, and the curing is carried out for 2-3 days depending on the weather conditions. After curing, the expansion joints are cut into the concrete. The cutting of the expansion joints should be combined with the design pattern to ensure the beauty of the texture pattern. After the expansion joints are cut, the curing should continue for 1 day. |

| Flushing | Rinse the cured concrete surface. The colored concrete texture pattern surface layer should use a high-pressure water gun to wash the floating materials on the surface and use a floor brush to flush and brush clean the demolding powder and dirt. The water pressure should be strictly controlled during flushing to avoid washing away the surface hardening. This work is very important. When cleaning the demolding powder, carefully observe the working surface to ensure that it is not missed, and there should be no large differences in color depth. The color distribution of a large area must be uniform. |

| Spraying of sealant | After the flushing is completed, when the colored surface layer is completely dry, use a special tool to spray or brush the sealant evenly on the colored surface layer. When spraying, take protective measures to prevent contamination of other buildings. During the construction process, pedestrians and vehicles are strictly prohibited from passing except for construction personnel. Passage will be allowed 12 hours after the construction is completed. |

Color Customization

Finished Product Maintenance

The construction of hardened embossed floor materials is generally carried out outdoors and should be avoided in rainy and windy weather. The construction environment temperature is generally above the daily average temperature of 5 degrees Celsius.

Rinse the floor surface: Wait for the embossed floor to be completely dry and solidified for at least 3-4 days before cleaning the surface with water or detergent. The cleaning surface must ensure that the cleaning degree of the entire floor is consistent, otherwise the color of the ground will be different.

Apply embossed floor protective agent: Wait for the surface of the cleaned embossed floor to be completely dry and free of moisture, and apply the embossed floor protective agent for at least one day to achieve the effect of maintenance and brightness enhancement.

During the maintenance stage of the embossed floor, it is necessary to prevent people from entering and exiting at will or carrying out other construction operations. The constituent materials and tools include color enhancer, coloring release powder, embossed floor protective agent, die and paper mold, special tools, etc.