Ceramic particle non-slip pavement

Product Application

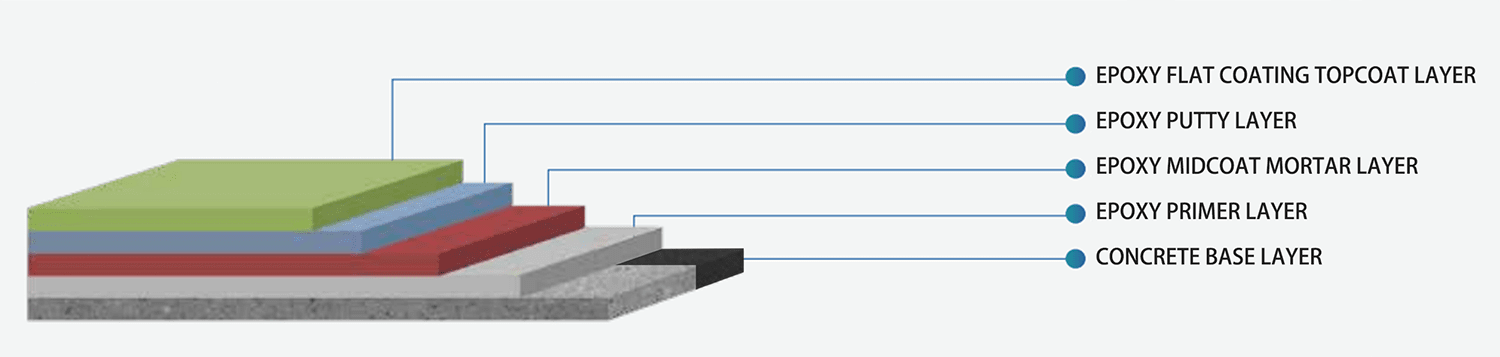

Ceramic Particle Non-slip Pavement Coating Structure

Construction Technology

| Construction sequence | Construction process | Optional materials | Construction method | |

| 1 | Concrete foundation | Grinding | ||

| 2 | Asphalt base | Grinding | ||

| 3 | Interface treatment agent | KS-301-1 Epoxy Floor Paint Primer | Scraping | |

| 4 | Wear-resistant layer | KS-401 Ceramic Particles | Scraping | |

| 5 | Wear-resistant and anti-skid aggregate | KS-401 Ceramic Particles | Scraping | |

| 6 | Anti-fouling topcoat | KS-401-1 Ceramic Particle Topcoat | Spraying | |

| Process name | Specific practices and requirements | |

| Base surface treatment | Basic ground requirements: if it is an asphalt base, the ceramic particle anti-skid pavement should be laid 1 to 2 months after the pavement is poured because the anti-skid glue contains solvents. If the asphalt of the newly paved asphalt pavement has not entered a stable period, the solvents in the anti-skid glue will damage the underlying asphalt. If it is a concrete base, the colored anti-skid ceramic particle pavement needs to be constructed after the pavement foundation maintenance is completed 1 month after the pavement is poured. The construction pavement must be ensured to be dry and flat. If the pavement is uneven, it will need to be repaired and polished first. Then use a high-pressure water gun to clean the pavement, and then construct after the pavement is completely dry. Before construction, use a high-power hair dryer to remove all dust and impurities on the pavement. | |

| Sealed primer application | When the base surface is cement, use the outdoor road special bonding primer to mix evenly according to the ratio and then use a mixing drum to roll it for construction, or use an airless spray machine to spray it once to make a comprehensive seal of the concrete floor. When constructing an asphalt pavement, you don’t need to apply the primer. | |

| Scrape and apply anti-slip glue | After mixing the special anti-skid glue for colored pavement evenly according to the ratio, use a rake with a mantou tooth to scrape and apply. The general thickness of the glue is 2 to 3 mm. If the pavement design has several colors, you need to paste the color separation paper according to each color and shape first, and then scrape and apply the anti-skid glue to blocks. | |

| Spread ceramic particles | Spread the colored ceramic particles evenly on the surface of the just-scraped and evenly applied colored anti-skid glue, and completely cover the resin material. (The recommended particle size of ceramic particles for bicycle lanes and sidewalks is [1-2MM]; for bus stops, and highways, ceramic particles are recommended to be [2-4MM]) Generally, about 5 kg of ceramic particles are used per square meter of ground. After spreading the colored ceramic particles, the ceramic particles can be recycled 4-5 hours after the normal temperature climate. The collected ceramic particles can be reused after secondary screening. | |

| Maintenance and spraying | According to the temperature change, it takes about 5-10 hours for the working surface to be completely hardened before pedestrians and vehicles can be allowed. In summer, the time for pedestrians and vehicles can be shortened. If some projects need to be sprayed with topcoat, you can directly spray one coat of topcoat, and the road will be open to pedestrians and traffic in about 5-8 hours. | |

Color Customization

Finished Product Maintenance

1. Regular cleaning: In order to ensure the cleanliness of the road surface, it is necessary to clean it regularly. This can remove dust, debris, and possible pollutants such as oil on the road surface. When cleaning, avoid using sharp or hard tools to avoid scratching the surface of the ceramic particle anti-skid pavement.

2. Waterproof and moisture-proof: The ceramic particle pavement should be kept dry to avoid long-term water accumulation. In the rainy season or in areas with high humidity, the drainage system of the pavement should be checked regularly to ensure smooth drainage and prevent moisture from eroding the pavement material. If the road surface is seriously flooded, it is necessary to clean the water well in time to find the cause of the water accumulation and to transform the drainage system if necessary.

3. Timely repair: Once the road surface is damaged, such as cracks, potholes, or detached ceramic particles, it should be repaired immediately. The damaged area should be cleaned before repairing, and then the repair material should be implemented.

4. Avoid overloading and speeding: Although the ceramic particle pavement has a strong load-bearing capacity, overloading and speeding should still be avoided to reduce the impact and wear on the road surface.

5. Regular inspection and maintenance: Regularly conduct a comprehensive inspection of the ceramic particle pavement, evaluate the condition of the pavement, and perform necessary maintenance and care as needed. For example, conduct regular anti-skid performance tests on the pavement to ensure that it always maintains good anti-skid performance.